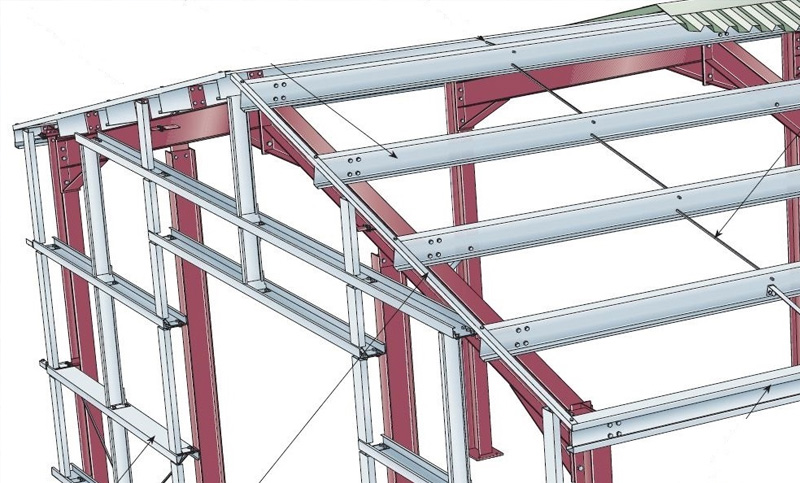

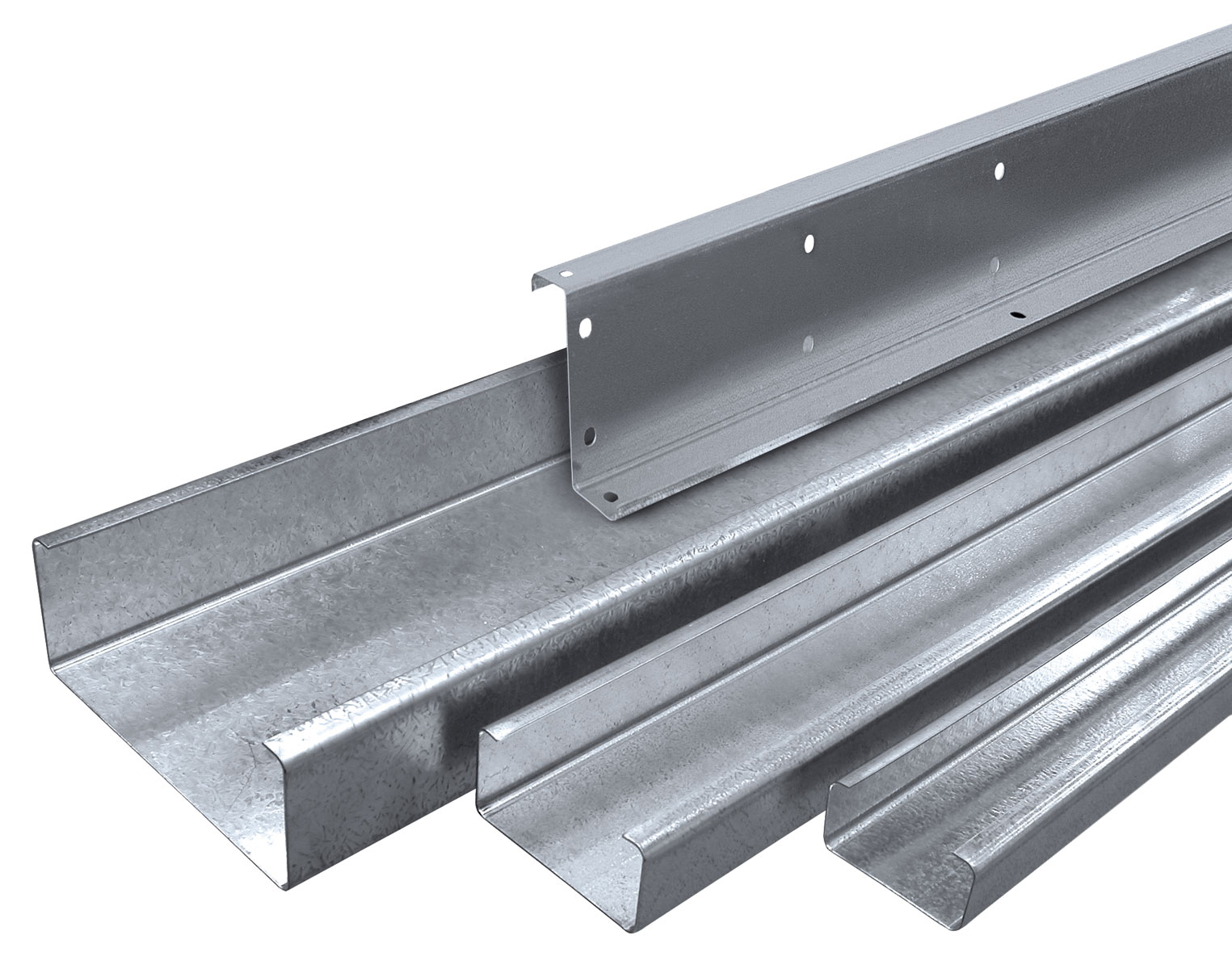

Stratco manufacture a complete range of structural C and Z purlins and girts for industrial buildings, garages, warehouses, and carports, in fact anywhere that strong, reliable steel framing is required. Manufactured from quality galvanized steel, this is a fully integrated system allowing for flexible design options.

Supplied plain or punched, galvanized purlins are manufactured from high tensile steel for increased strength, reduced weight, and a long serviceable life.

In architecture, structural engineering or building, a purlin (or historically purline, purloyne, purling, perling) is a horizontal beam or bar used for structural support in buildings, most commonly in a roof. Purlins are supported either by rafters or the walls of the building. They are most commonly used in metal buildings, though they sometimes replace closely spaced rafters in wood frame structures.

The purlins of a roof support the weight of the roof deck. The roof deck is the wood panel, ply board, or metal sheeting that creates the surface of the roof. When made of wood, it is usually covered with some sort of weatherproofing and sometimes an insulation material.

Several kinds of purlins exist. They are divided into categories based on the material from which they are made and their shape. Different purlins are used for different purposes, including structural support of walls or floors. Purlin is important because without it, there’s no frame for the sheeting on the roof to rest on, making purlins critical to the structure of the roof.

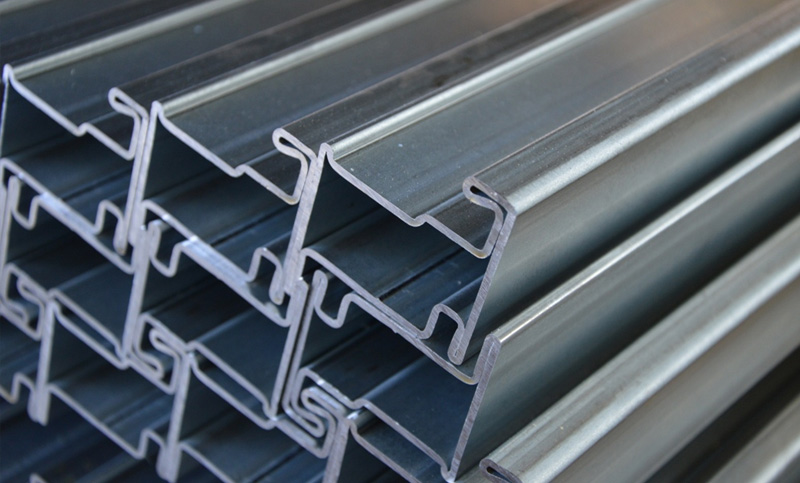

Cold-formed steel roof purlins and side rails are manufactured from pre-galvanised steel strip, in the form of coils, which have been slit to the desired width from the parent or “wide coil” supplied from the mills.

The purlin is formed gradually by feeding the strip continuously through successive pairs of rolls, which act as male and female dies. Each pair of rolls progressively forms the strip until the finished profile is produced. For example, five to eight “stages” or “passes” will be needed to form a lipped Z purlin, depending on the thickness of the material. More complicated profiles will require 15 or more passes.

Steel Purlin

Steel Purlin is a direct replacement for wood purlin. They are light weight, dimensionally stable, accurate and straight. They expand and contract reasonably in extreme temperature changes.

Steel purlin is usually made of cold-formed steel that is thin enough to put screws through. Cold-formed steel is made by rolling or pressing thin sheets of steel into the desired shape. It is less expensive for the manufacturer than hot-rolled steel and is also easier to work with. Though cold-formed steel is stronger than hot-formed steel, it is more likely to break when under pressure rather than bend.

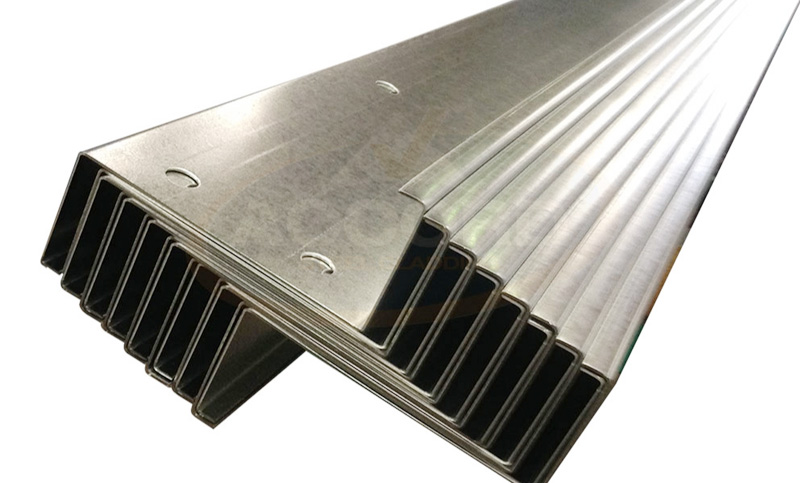

Purlins are manufactured from hot dipped galvanized steel with a coating, in line with other common lightweight steel structural building products. This gives good protection in most exposed internal environments. Run off from, or contact with, materials which are incompatible with zinc should be avoided.

To protect the purlin, they also apply a layer of paint outside them. Zinc and paint in combination (synergistic effect) produce a corrosion protection approximately 2X the sum of the corrosion protection that each alone would provide.

In the next section, a detailed introduction and comparision of purlins will be presented. Understanding that purlins have a growing importance in construction works, Chinh Dai Steel have been perfecting our technology to supply c channel purlin and z purlin of highest quality.

· They are cost effective in comparison to heavier, hot-rolled steel angle and channel profiles

· They have a high strength-to-weight ratio

· Long spans of up to 15m are possible

· Pre-galvanised sections provide longer-term durability

· Material is delivered to site pre-punched and cut to length

· They are lightweight and are easy to handle and construct

· Steel is 100% recyclable.