Steel Structure – The Future of Structure

A steel structure building is a metal structure fabricated with steel structure frame for the internal support and for exterior metal claddings, as opposed to steel framed buildings which generally use other materials for floors, walls, and external envelope.

If you’re looking for the most cost-effective building, it’s important to consider your potential long-term savings along with your initial investment in different kinds of steel structures, let’s think about steel structure buildings.

Steel structure is a metal structure which is made of structural steel components connect with each other to carry loads and provide full rigidity. Because of the high strength grade of steel, this structure is reliable and requires less raw materials than other types of structure like concrete structure and timber structure.

In modern construction, steel structures is used for almost every type of structure including heavy industrial building, high-rise building, equipment support system, infrastructure, bridge, tower, airport terminal, heavy industrial plant, farm shed,pipe rack, etc.

Compared with traditional buildings, Steel Structure Building Construction offers an innovative type of building structure—the entire building made of steel. The structure mainly comprises steel beams, columns, trusses, and other parts made of thin-walled steel and steel plates. It is connected between parts and parts by welding, bolts, or rivets. The lightweight and simple structures are widely used in large factories, stadiums, super high-rise buildings, and other fields.

Steel Structure Building Construction provides affordable, durable, and low-maintenance solutions for workshops, warehouses, agricultural buildings, garage buildings, and aircraft hangars. Compared to wooden structures, steel is resistant to strong winds, heavy snow, and termites. The interior layout of the metal buildings can be fully customized to meet your different requirements.

Steel Structure detail shows the specification of the portal frame structure, which most common use building structure for Warehouse, Workshop, Garage, and Aircraft Hangar.

The steel structure is a structure mainly made of steel, and it is one of the main types of building structures. The characteristics of steel are high strength, lightweight, excellent overall rigidity, and strong deformability. So it is especially suitable for large-span, super-high and super-heavy buildings. The steel structure is a steel beam, steel column, steel truss, and other components made of section steel and steel plate, and welds, bolts, or rivets connect each component or part.

The lightweight portal frame is a single-story steel building, which beams and columns rigidly connected. It has the advantages of simple structure, lightweight, and all the components manufactured in the factory, easy for assembling on site.

The portal frame steel structure widely used for Industrial, commercial, and agricultural buildings, such as steel warehouse, workshop building, Storage, Poultry building, and aircraft hangar.

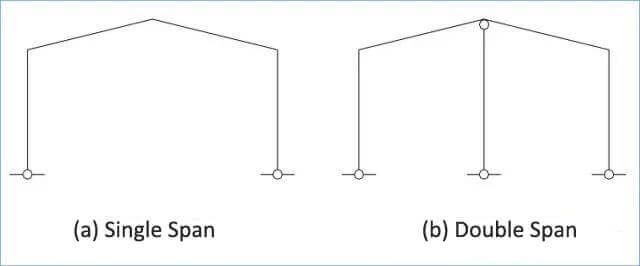

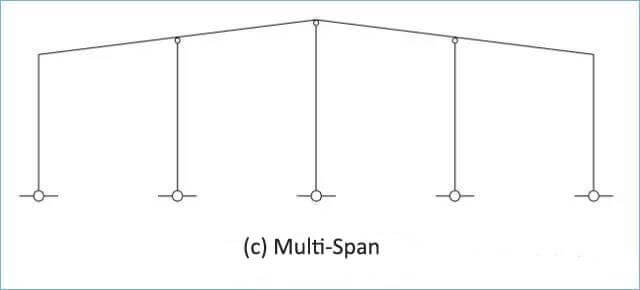

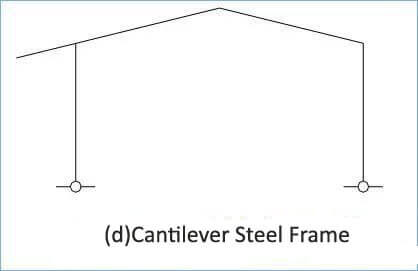

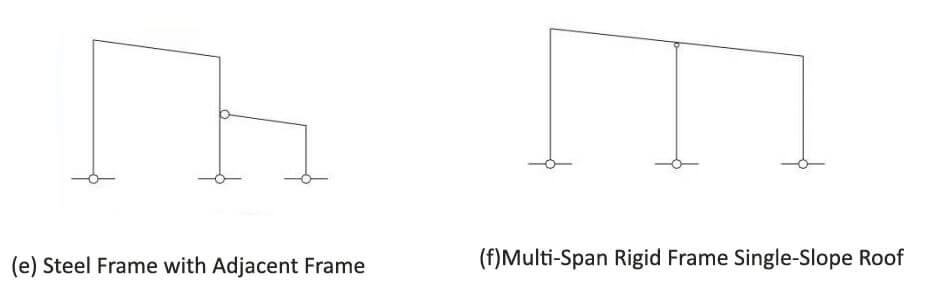

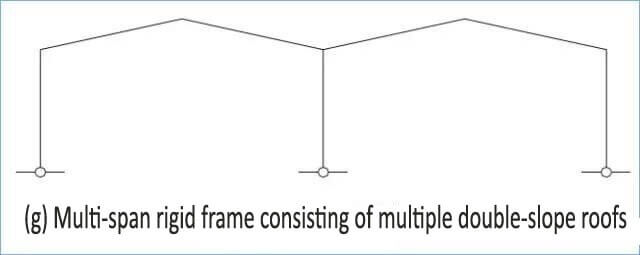

The portal frame can divide into single-span (Figure a), double-span (Figure b), multi-span (Figure c) cantilever steel frame (Figure d) ) and steel frame with the adjacent frame (Figure e).

In the multi-span rigid frame, the connection between the column and the roof beam generally hinged, and the multi-span rigid frame single-slope roof (Figure f).

The multi-span rigid frame consisting of multiple double-slope roofs can also be used (Figure g). The beam-column cross-section can be equal or variable, and the base of columns hinged or rigid connected.

Generally speaking, according to the principle that the long side is greater than the width, the amount of steel used in the rigid frame can be reduced, and the support between the columns can be reduced, thereby reducing the amount of metal used in the support system.

Example 1: The size of the building is 60x50m, 60m should use as the length and 50m as the width, that is: 60 (L) x50 (W), not 50 (L) x60 (W).

The most economical column distance under standard load is 7.5-9m. When it exceeds 9m, the steel consumption of roof purlin and wall girt will increase too much, and the overall cost is not economical. The standard load here refers to 0.3KN / m2 for live roof load and 0.5KN / m2 for essential wind pressure. When the loading is more significant, the economic column distance should reduce accordingly. As or workshop building with more than 10 tons crane, the financial column spacing should be 6-7m.

When arranging column spacing, if unequal column spacing is required, try to arrange the end span column spacing to be smaller than the center span. It is because the wind load at the end span is larger than the center span. Besides, when using continuous purlin design, The deflection of the end span and the mid-span bend are always more significant than other spans. Using smaller end spans can make roof purlin design more convenient and economical.

Example 1: Building length = 70m

Economical column distance is available: 1 @ 7 + 7 @ 8 + 1 @ 7 or 1 @ 8 + 6 @ 9 + 1 @ 8

Example 2: Building length = 130m, with a 10-ton crane

Economical column distance is preferable: 1 @ 5.5 + 17 @ 7 + 1 @ 5.5 or 20 @ 6.5

Different production processes and use functions largely determine the span of the metal building. Some owners even require steel building manufacturers to determine a more economical span based on their useful features. A reasonable span should decide according to the height of the steel building. In general, when the column height and load are constant, the span is appropriately increased. The increase in steel consumption of the rigid frame is not apparent, but it saves space, the foundation cost is low, and the comprehensive benefits are considerable.

Through a large number of calculations, it finds that when the eaves height is 6m, the column distance is 7.5m, and the load conditions are entirely consistent, the steel consumption of the rigid frame (For Q345B steel) width between 18-30m is 10-15kg / m2. The amount of metal used for rigid frame units between 21-48m is 12-24kg / m2. When the eave height is 12m, and the width exceeds 48m, a multi-span rigid frame (sway column set in the middle) should use. The frame saves more than 40%, so when designing the rigid portal structure, you should choose a more economical span according to specific requirements, and you should not pursue a large span.

The roof slope decides according to comprehensive factors include the structure of the roof, the length of the drainage slope, and the height of the columns. Generally, it is 1/10 ~ 1/30. Studies have shown that different roof slopes have a significant impact on the amount of steel used in rigid steel frames. The following is the result of the calculation and analysis of the steel consumption under different roof slopes with a single span of 42m and an eave height of 6m.

When the roof slope is 0.5: 10, the weight of a frame is 3682 Kg when the roof slope is 1: 10, the amount of a frame structure is 3466 Kg When the roof slope is 1.5: 10, the weight of a frame is: 3328 Kg When the roof slope is 2: 10, the amount of a frame structure is: 3240 Kg.

So for a single-span rigid frame, a better way to reduce the weight of the rigid frame is to increase the roof slope. The larger the hill, the less steel used. However, the situation is different for a multi-span frame. A large slope will increase the amount of metal used in the frame. It is because a large hill will increase the length of the inner column.

When the span of the building is large, increasing the incline can reduce the deflection of the roof steel beam. Through research and calculation, the more economical slope is: multi-span buildings: 1:20 single span, span less than 45 m: 0.5: 10 single span, span less than 60m: 1.5: 10 single span, more than 60 m span : 2: 10

The roof slope is also related to whether the building has a parapet wall, and the large hill will lead to an increase in the cost of the parapet wall.

The eave height has a significant impact on the cost, which mainly manifested in the following aspects:

Temperature section

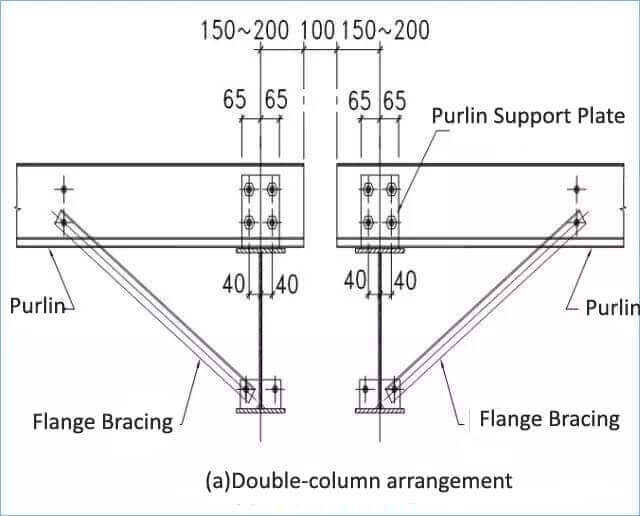

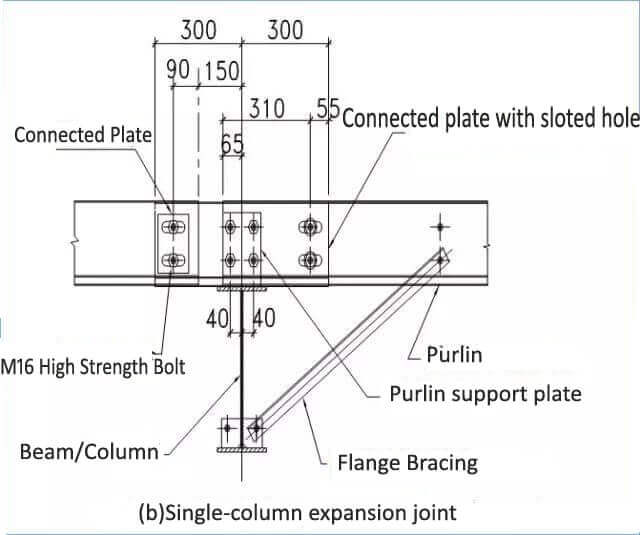

According to the code of steel structure building, the maximum length is not more than 300m, and the width is not more than 150m. The first temperature segmented expansion joint can set with a double-column arrangement (Figure 2a) or a single-column expansion joint with slotted holes connected to the purlin (Figure 2b).

(A) the use of the Bracing

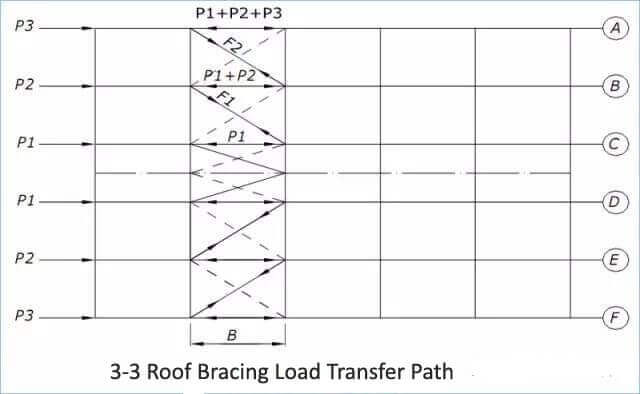

In the longitudinal structure of the portal frame, a complete bracing system should arrange to form a whole spatial structural system. The lateral stability of the lightweight portal frame in the width direction is ensured by the rigidity of the frame to resist the lateral load.

Due to the weak stiffness of the longitudinal structure in the length direction, it is necessary to set bracing in the longitudinal direction to ensure its longitudinal stability. The forces of bracing are mainly longitudinal wind load, crane braking force, earthquake action, and temperature action. When calculating the internal strength of brace, the joints are generally assumed to be hinged, and the effect of eccentricity ignores. The general support considered according to the tie bean. Therefore, a two-way arrangement is suitable.

(B) Common types of bracing

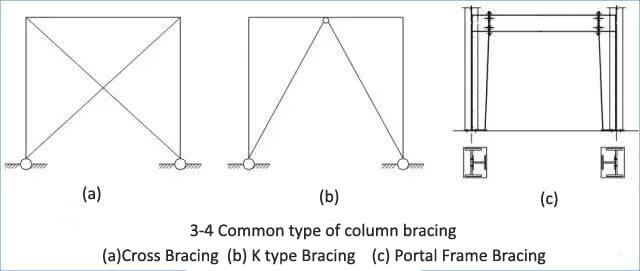

Figure 3-3 shows the general arrangement of roof bracing and the force transmission path of wind loads acting on the gable wall. Figure 3-4 shows the common support types between columns for portal frames. Due to building function and appearance requirements, or process equipment layout, when the above supports are not allowed to use, consider using a longitudinal structure. At this time, the bending stiffness of the weak axis of the column needs to use.

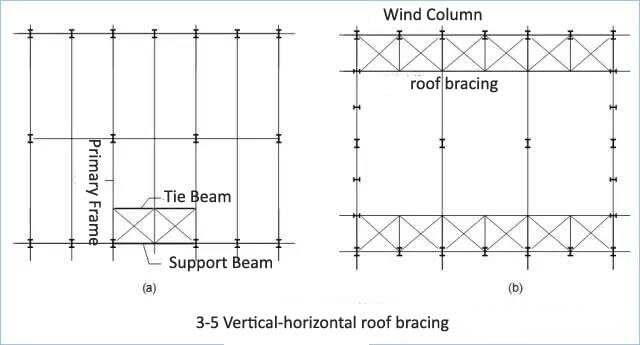

(1) When there is a removing column(In the column net, one or more columns are removed), such as a local removing column, only longitudinal bracing is required, as shown in Figure 3-5a;

(2) When the column distance is large, and the side column adopts the scheme of false wall frame column, see Figure 3-5b;

(3) The tonnage of the crane is greater than 15 tons.

When the building width is greater than 60m, it is appropriate to increase the column bracing. When cross bracing cannot be arranged, the bracing forms are shown in Figures 3-4b and 3-4c can be used. It is also possible to increase the section size of the roof bracing or the column bracing without increasing the internal inter-pillar support. At this time, the internal force calculation needs to be strictly performed to ensure the bracing is safe.

In the same column, different types of bracing should not be mixed, otherwise, the bracing with small stiffness will have less force and will not function as it should, and the bracing with high rigidity will be damaged due to overload work. The columnBracing should preferably choose to use cross braces.

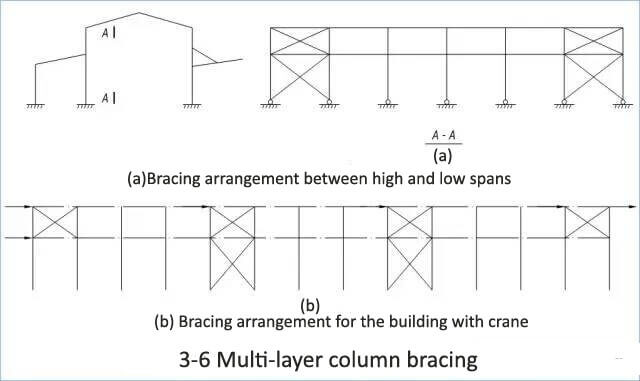

(1) When there is a high-low span (or with a large rain canopy), the upper and lower bracing between the columns need to be layered at the high-low span (or the large rain canopy) (see 3-6a);

(2) When the eave height is greater than 9m, double-layer column bracing can be set according to the included angle of the bracing. The angle between the cross-bracing and the horizontal plane is preferably 45 °, and it should not be greater than 55 °. The upper and lower bracing are set between the columns. The end-opening room may not be provided with a lower bracing to reduce the temperature stress of the crane beam (see 3-6b).

When the internal force of column bracing is large or the lifting tonnage of the crane is more than 5 tons, round steel support is not suitable. At this time, it should use angle steel Or round (square) pipe as column bracing.

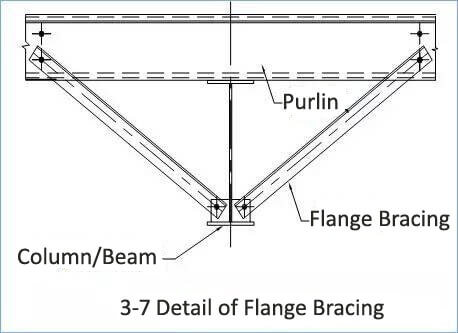

The function of the flange bracing is mainly to prevent the instability of the lower flange of the beam and the inner flange of the column. The brace is connected to the lower flange of the beam on one side and the purlin on the other. Refer to Figure 3-7 for the practice of bracing.

Steel is high structural reliability, suitable for bearing impact and dynamic loads, and excellent seismic performance.

The internal structure of the steel is uniform, close to an isotropic homogeneous body. The actual working performance of the steel structure is more in line with the calculation theory. Therefore, the steel structure has high reliability. Compared with concrete and wood, the ratio of density to yield strength is relatively low. Thus, under the same stress conditions, the steel structure has a small section, lightweight, convenient transportation, and installation, and is suitable for large spans, high heights.

When the temperature is below 150°C, the properties of the steel change little. Therefore, the steel structure is suitable for hot workshops, but when the surface of the structure is exposed to the heat of about 150°C, it should protect by heat insulation panels.

When the temperature is between 300℃ and 400℃, the strength and elastic modulus of the steel will decrease significantly, and the strength of the steel will tend to zero when the temperature is around 600℃. In buildings with special fire protection requirements, the steel structure must be protected by refractory materials to improve the fire resistance level.

Especially in the environment of the humid and corrosive medium, it is easy to rust. Generally, steel structures must be de-rusted, galvanized, or painted, and regularly maintained. For offshore platform structures in seawater, special measures such as “zinc block anode protection” are required to prevent corrosion.

Steel structural components are natural to manufacture in factories and assembled on site. The factory mechanized manufacturing of steel structural components has high precision, high production efficiency, fast site assembly, and a short construction period. The steel structure is the most industrialized.

Compared with ordinary reinforced concrete structures, steel structures are superior in inhomogeneity, high strength, fast construction, good seismic resistance, and high recycling rate. Steel has many times higher strength and modulus of elasticity than masonry and concrete, so the mass of steel members is light under the same load conditions. From the aspect of being destroyed, the steel structure is a flexible damage structure with large deformation foreshadowed in advance, which can detect the danger in advance and thus avoid it.

There are three conventional steel building structure connections: welding connection, rivet connection, and bolt connection.

Welding Connection

The welded connection is the primary connection method for steel structures.

According to the relative positions of the two weldments: butt weld, overlap weld, T joint, and corner joint.

Bolt Connection

Bolt connection is divided into ordinary bolts and high-strength bolts.

Ordinary bolts are for temporary connection and the connection of removable static load structures.

High-strength friction bolts are currently widely used in industrial, civil construction steel structure connections. They are the most suitable connection method for bearing dynamic loads among various links.

Rivet Connection

A rivet is a type of tight member composed of a head and a nail rod. It mainly completes the connection work by the friction generated by its deformation. The specific connection methods include cold riveting and hot riveting.