Cold room&cold storage Summary

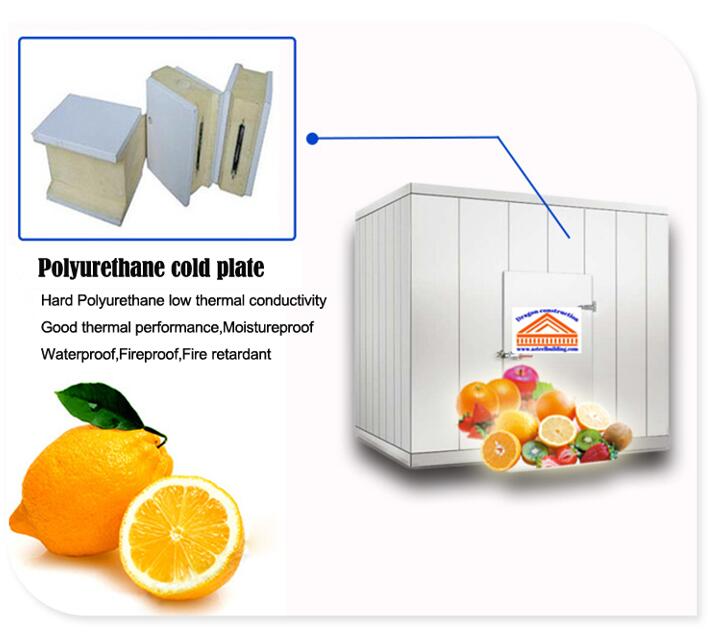

What is cold room or cold storage? A refrigerating chamber or cold room is a warehouse in which a specific temperature is artificially generated. It is generally designed for storing products in an environment below the outside temperature. Products that need refrigeration include fruits, vegetables, seafood, meat, flowers and so on.

Our walk-in cold rooms offer reliable, efficient environmental controls for a variety of applications which including: GMP Storage and Cold Storage for Seeds and Agricultural Products, Nutritional Supplements, and so on. Our cold rooms are typically supplied with desiccant or refrigeration based dehumidification in order to maintain a low dew-point and prevent ice accumulation on both product and equipment surfaces. Typical temperatures for our cold rooms range from of -40°C to 10°C.

One of The man products of Dragon Construction are cold storage devices and supporting host and auxiliary equipment with various temperature levels and different specifications,as well as cold room&cold storage accessories. According to the different requirements of customers,we provide artificial climate chamber, special cold storage for mushroom cultivation, as well as cold storage for fruits and vegetables, fresh produce and ordinary frozen foods. We also provide specialized ultra-low temperature cold storage, rapid freezing cold storage for production and processing, as well as combinations of different types of cold storage mentioned above. Our products are able to meet the needs of large or medium-sized enterprises in food production and storage, hotels and catering services, pharmaceuticals and chemical companies, fruit and vegetable planting or management farmers fresh food preservation, storage and transportation industry,, research institutions and so forth.

Features

STANDARD FEATURES

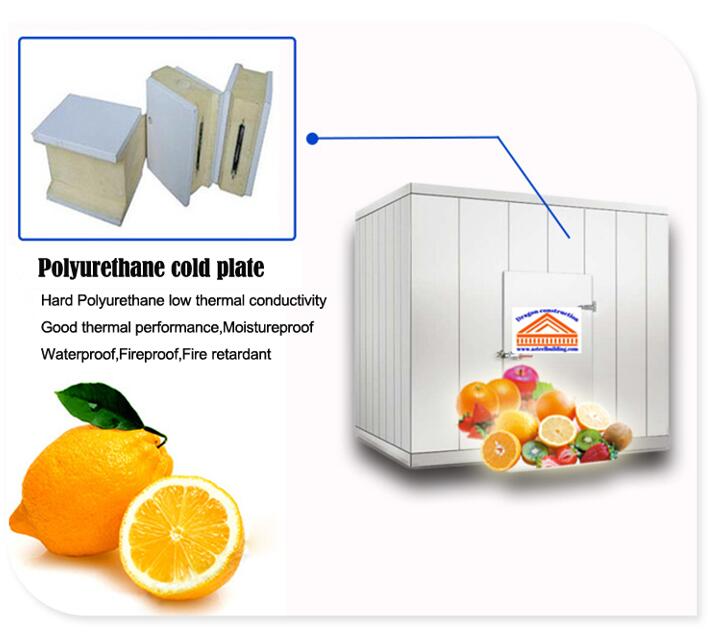

- 50mm to 200mm thickness Polyurethane Foam Insulated Panels,R- Value 31+ or Higher

- Embossed White Aluminum Interior Surface Finish

- Embossed White Galvanized Steel Exterior Surface Finish

- Exceptional Temperature Uniformity

- Temperature Control At Sensor / Set-Point: ±0.2° C

- Humidity Control At Sensor: ±0.5%.

- High / Low Alarms

- Flexible Configurations

- Complies With LEED Standards

- Energy Efficient Offering Lowered Maintenance Costs

- Pre-tested, Pre-charged Refrigeration Systems

- Non-proprietary Controls

- Corrosive Resistant Equipment

- Precision Sizing

- Diurnal Cycling Temperature

OPTIONAL FEATURES

- Added Dehumidification and/or Ultrasonic Humidification

- Extended Temperature And Humidity Ranges

- Stainless Steel / Special Surfaces

- Ethernet / Remote Monitoring / Alarming

- Corrosive Resistant Equipment

- Added Redundancy in Controls and/or Conditioning system

- Data Logging

- Water-Cooled Or Air-Cooled Condensers

- Custom Lighting Systems

- High Density Shelving

- Unlimited Door / View Window Sizing

- Insulated Glass View ports

- High Weight Capacity Flooring

- Calibration / Validation / Maintenance Services

- Touchscreen Control Interface

- Antimicrobial Coating on door handle to reduce the spread of bacteria and pathogens.

There are many advantages of our customized design:

- No standard dimensions. No modular system. Our products are customized for the needs of our customer. We can manage all of your special demands such as glass doors, special floor, silent condensing unit, shelving system, etc.

- Can be customized to suit individual needs

- Exact panel connections at the corners

- Various types and custom design

- Always a custom look

- Easy and quick assembly

- Dismountable design – easy to resettle

- Long durability perfect construction

- Energy saving with customized PU panels

- Efficient space utilization

- Balanced refrigeration system

- Commercial cold room & freezer production and installation from our professional company.

- Our cold rooms and freezers are made of modern PU/PIR panels, which fulfils all of hygienic and authority requirements. Special panels for example firesafe and PE coated types are available.

- As cold room specialists we know exactly how to design, plan and install cold rooms and freezers. We have lot of tips to operate your cold stores from planning to every day using.

- We can manage DIY system as well. You can order the materials only without installation. In this way you can save the cost of installation. (Be careful! Installation of cooling system needs special skills and tools!)

- We support other cold room owners who currently use other type of cold rooms or freezers. We can produce doors and other spare parts to replace damaged ones.

- Doors are one of the most important parts of a cold room. We can produce the strongest IglooDoors cold room doors in any dimensions.

- Very competitive price level because the customized panel system and professional cost saving solutions

Technical parameters of our commercial cold rooms:

- Dimensions: unlimited sizes and design

- Panel thickness: from 40 mm to 200 mm

- General coldroom panel thickness: 80 mm

- General freezer panel thickness: 100 – 120 mm

- General temperatures for coolers: 0/+5 C

- General temperatures for freezers: -18/-20 C

- Panel surface: Standard: powder coated in RAL colour tones, or Stainless steel (circle finish, strip finish, mirrored-finish, bright polish, patterned, etc)

- Electricity: 230V or 380V depending on dimensions

- Condensing water: evaporated or drained

- Door types: solid hinged or sliding, glassed, full glass, fire rated, electronic operated, etc.

- Door opening dimensions are individual!

- Corners and panel joints: with special Labyrinth bending without corner covering (standard hygienic corners), or normal panel bending with corner covered PVC equipment

- Door thresholds: With or without threshold. Suggested to lift the cold room’s floor to the outside surface (without threshold). If threshold needed, it can be heated.

- Air condensing units: Efficient and economy models of well-known brands such as Copeland, Fras cold, Tecumseh L’unite, Bock, Bitzer, etc. Air condensing units can be installed to the top of the cold room/freezer, or outside. Silent models are available! All condensing units are equipped with heating elements for outside use!

- Evaporators: Professional technology for the proper cooling inside the cold rooms/freezers. Air flow and silent heat exchange are available for refrigerated cabinets!

- Controllers: In most cases we install electrical controlled automatic controls. Used technology is starting from simple models to the all-in one full supervising controllers. Cold room temperature registration equipment is available! (connected to central control system, or individual recording to memory or paper-based printers)